Product Brief

Flash valve

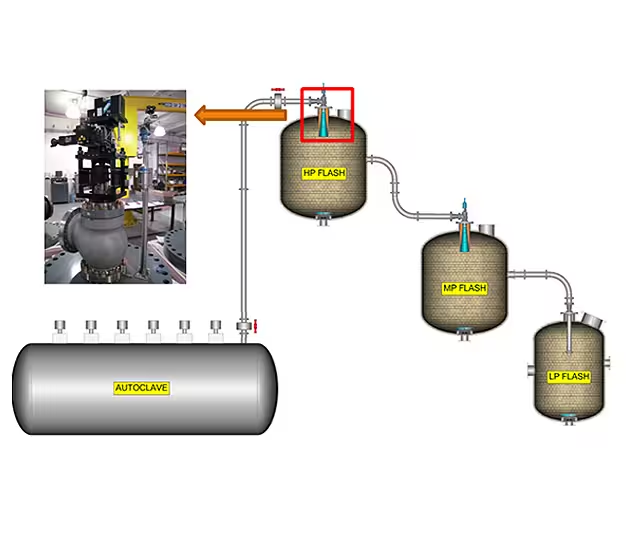

Flash valve is installed atop the high-pressure flash tank of pressure leaching autoclave, which is used to control the liquid level within the autoclave and flash-evaporate the discharged material for pressure reduction and cooling. This equipment series is widely used in smelting processes for nickel laterite ore, gold ore and copper-cobalt ore.

SERVICE CALL+86 13521339794

SERVICE CALL+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

Advantages & Features

1. Corrosion-resistant materials

1. Corrosion-resistant materials

Titanium alloy-clad ceramic or pure ceramic is employed to withstand high-temperature sulfuric acid corrosion. 2. Wear-resistant design

2. Wear-resistant design

The valve flow path features a converging-diverging structure to achieve gas-liquid phase equilibrium in the injection pipe, thereby reducing erosive wear from solid particles in the slurry. 3. Multi-stage pressure reduction

3. Multi-stage pressure reduction

Multi-stage pressure reduction prevents premature failure of the flash tank caused by excessive single-stage pressure drops. 4. Automatic control

4. Automatic control

The DCS system regulates valve opening degrees in real-time to adapt to process parameter variations. 5. Emergency isolation function

5. Emergency isolation function

The valve instantly close under abnormal conditions to prevent incident escalation.

Working Principle

1. Pressure energy converts to flash evaporation energy.

Slurry from nickel laterite ore processed in the high-pressure autoclave remains at temperatures above 250°C and pressures around 5 MPa. Flash valve instantly reduces slurry pressure, causing partial liquid in the slurry to be vaporized due to boiling point reduction and forming a gas-liquid two-phase flow. This process follows thermodynamic equilibrium principles, achieving autonomous phase transition through pressure energy release without external heat input.

2. Trigger point for gas-liquid separation Flash valve acts as pressure-reducing device, where orifice designs create localized resistance, causing abrupt increases in slurry velocity and sharp drops in static pressure. When pressure falls below the saturated vapor pressure of the liquid at that temperature, water and acidic components in the slurry rapidly evaporate, releasing dissolved metal ions (e.g., nickel, cobalt).

3. Thermodynamic equilibrium control The flash process adheres to Henry's law and sensible-latent heat conversion principles. During pressure reduction, sensible heat stored in the slurry partially converts to latent heat, leading to liquid vaporization; Simultaneously, steam byproducts recover thermal energy via preheaters to warm incoming slurry, enhancing system energy efficiency and enabling green recycling.

2. Trigger point for gas-liquid separation Flash valve acts as pressure-reducing device, where orifice designs create localized resistance, causing abrupt increases in slurry velocity and sharp drops in static pressure. When pressure falls below the saturated vapor pressure of the liquid at that temperature, water and acidic components in the slurry rapidly evaporate, releasing dissolved metal ions (e.g., nickel, cobalt).

3. Thermodynamic equilibrium control The flash process adheres to Henry's law and sensible-latent heat conversion principles. During pressure reduction, sensible heat stored in the slurry partially converts to latent heat, leading to liquid vaporization; Simultaneously, steam byproducts recover thermal energy via preheaters to warm incoming slurry, enhancing system energy efficiency and enabling green recycling.